Overview

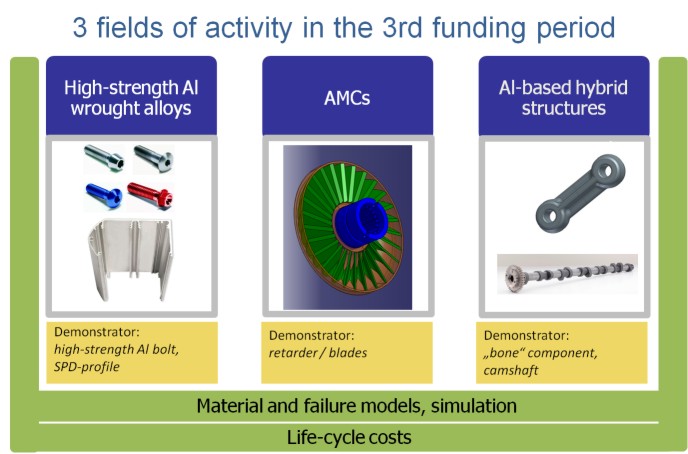

The key goal of the Collaborative Research Center SFB 692 is to fully utilize the potential of aluminium-based light-weight materials whil taking into account the many influencing factors during processing. Our research is focused on the development, production, characterization and application of novel light weight materials in safety-related parts and components. There are three main fields of activity: “high-strength Al wrought alloys”, “aluminium matrix composites (AMCs)”, and “Al-based hybrid structures”.

Research in the first field of activity is focused on producing very fine grains in wrought aluminium alloys, which leads to exceptional combinations of strength and ductility. Grain refinement is achieved by severe plastic deformation (SPD) processing, particularly using the equal-channel angular pressing (ECAP) method. The fundamental processes that govern deformation and microstructural evolution during SPD processing will in the third funding period be studied by micro- and continuum mechanical modeling. Moreover, the effect of cryogenic conditions on the maximum achievable degrees of deformation and on failure by shear localization will be investigated. In a novel transfer project, an SPD process to produce a shaped billet by room temperature extrusion will be developed for the first time.

Project areas

The SFB Team

Research in SFB 692 is performed in different project areas:

In project area A, new materials (with UFG microstructures, or with particle-reinforcements) are developed. Materials and billets with homogeneous microstructures (sub-projects A1 and A2) as well as materials with gradient microstructures (sub-project A4) are investigated.

Project area B is focused on the design and properties of surfaces, microstructural interfaces and interfaces in billets and components of the new hybrid structures. Corrosion and conversion behavior (sub-project B2) as well as the mechanical behavior of pre-damaged interfaces (sub-project B3) are considered.

In project area C, damage and failure during cyclic loading (sub-project C1), localized deformation during ECAP (sub-project C5), and new constitutive models for mechanical simulations (sub-project C2) are considered. In sub-project C4, relevant economic aspects are studied.

The sub-projects of project area D are focused on cutting (sub-project D2), and electrochemical (sub-project D5) surface treatments or machining, as well as on joining (sub-project D6) of the new materials.

The project area T encompasses new transfer projects, where – together with partners from industry - relevant scientific results are brought to use in specific applications.